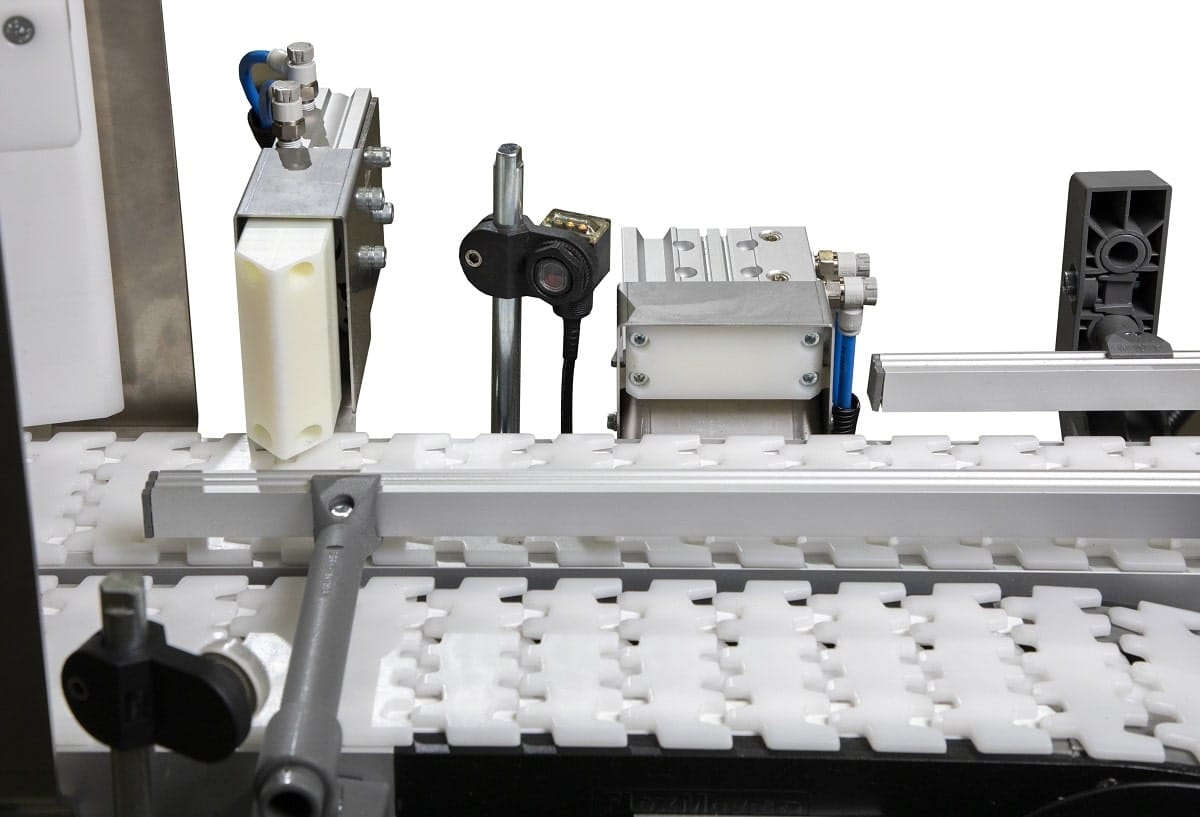

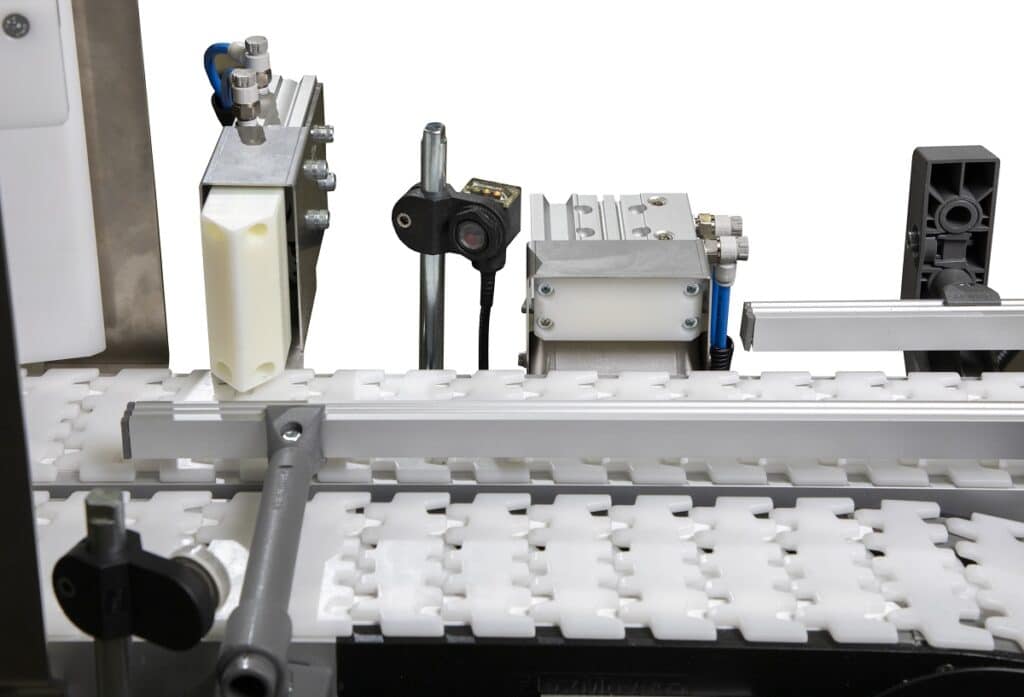

Puck Stop Module

Contact Us

Conveyor specialists are ready to help you find the right solution

Benefits of the Puck Stop Module:

- Pneumatic stop for pacing pucks or packages

- Two Models available:

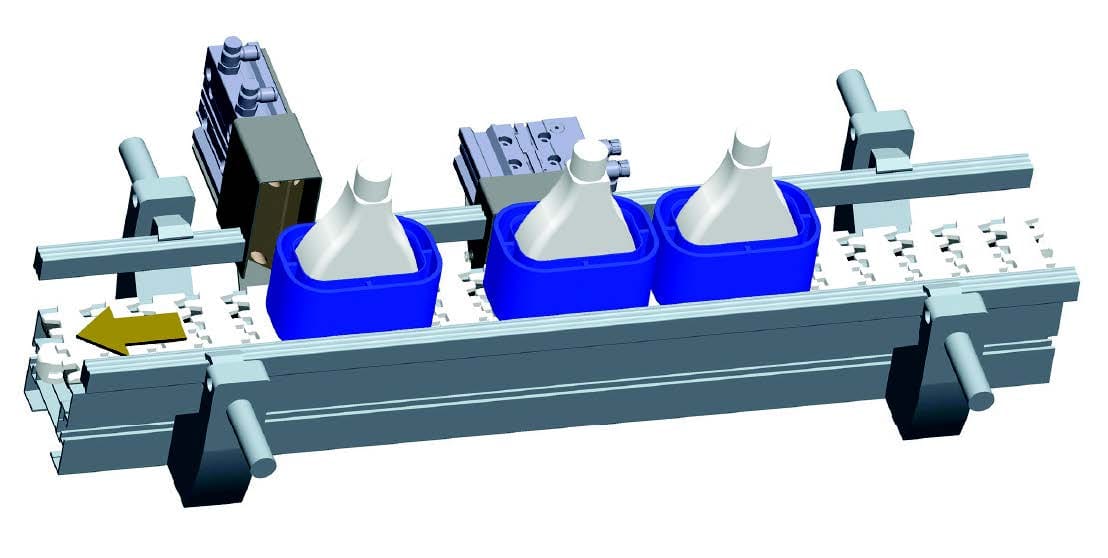

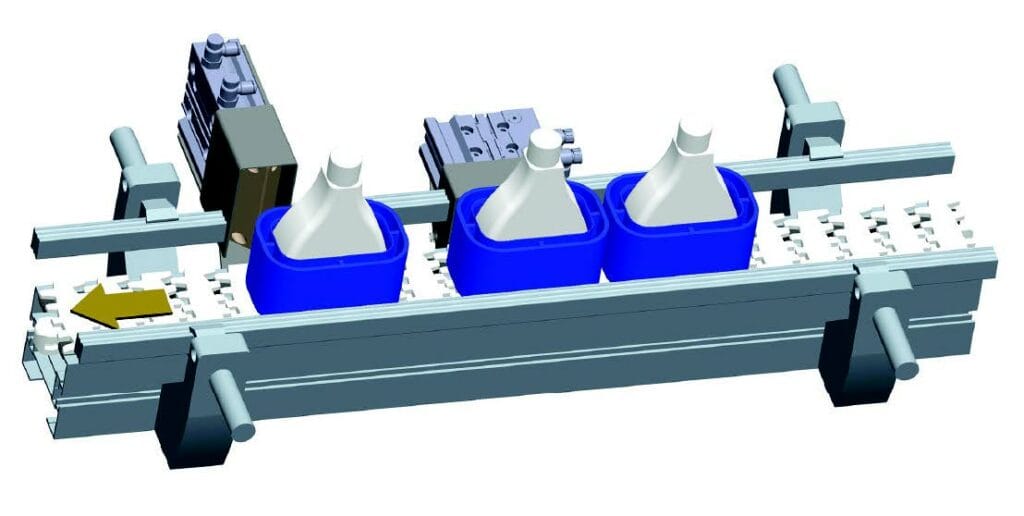

- Vertical Blade Stop: used in pairs as an alternating escapement for pacing round or rounded edge rectangular pucks

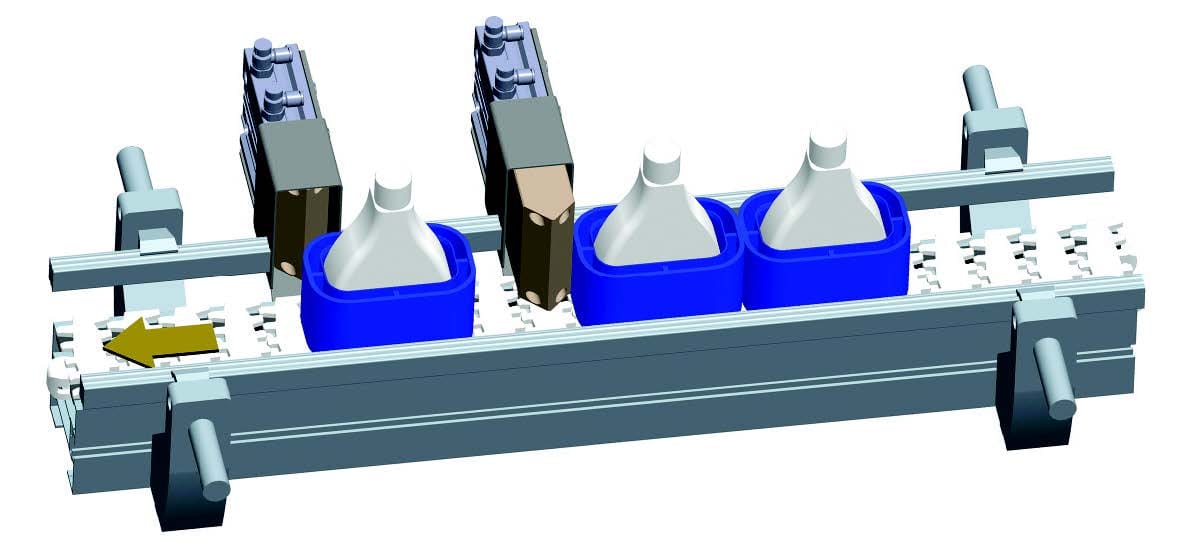

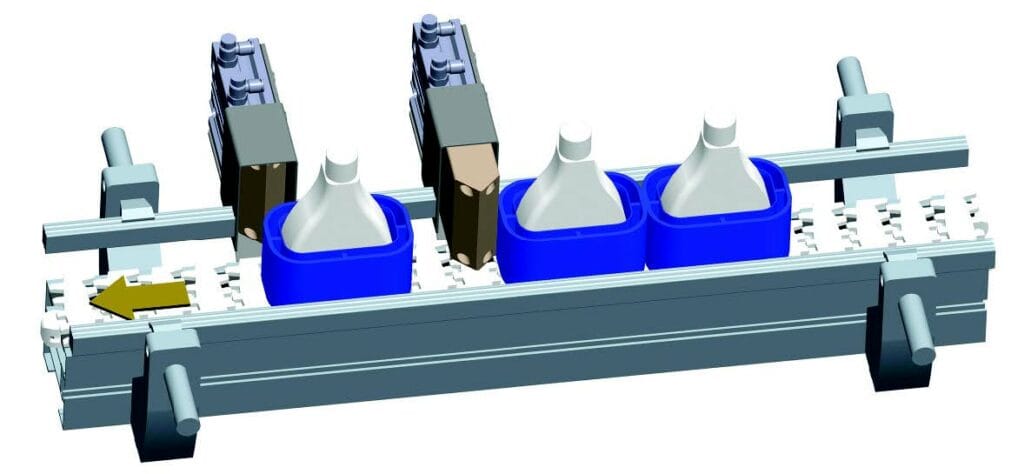

- Horizontal Squeeze Stop: used in combination with Vertical Blade Stop for pacing product without rounded edges. Product must be able to withstand side squeeze pressure

- Compatible with round or rectangular bottles, containers or pucks

- UHMW face for non-marking contact surface

- Includes flow controls with push-in air line connection

Features & Specs:

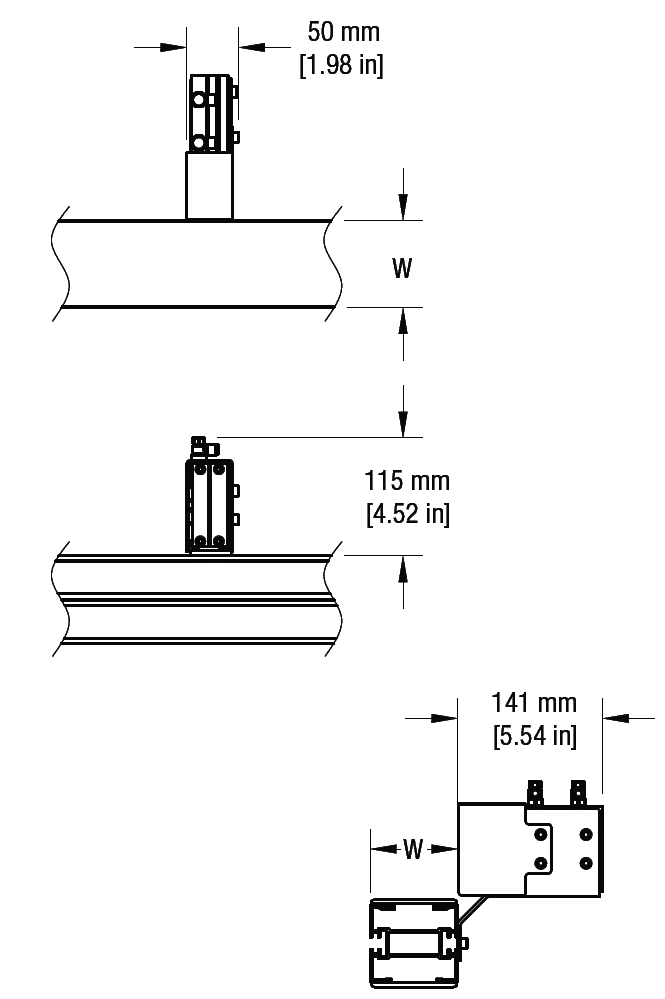

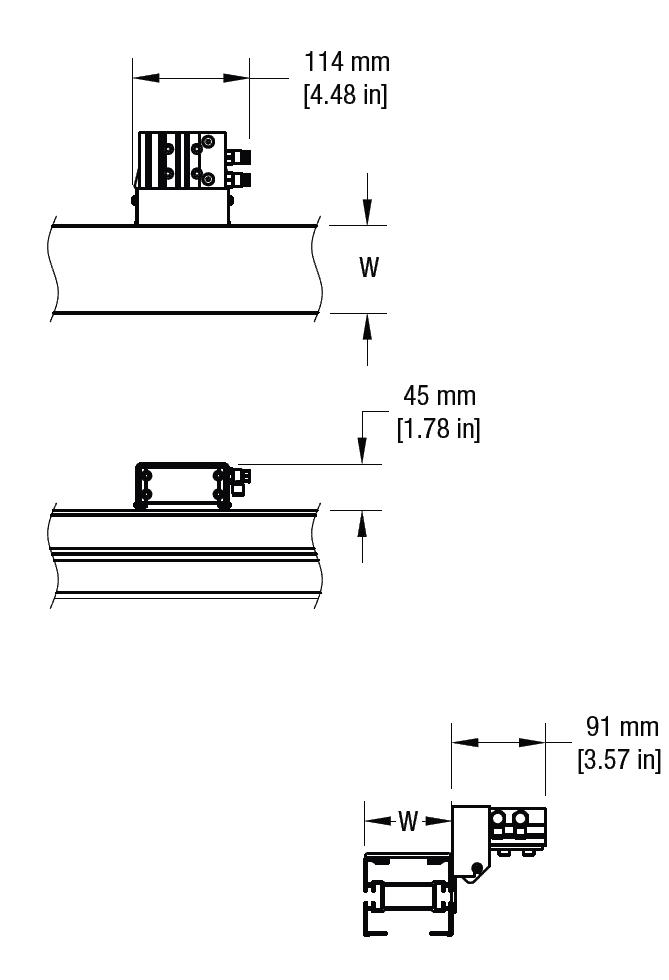

- Available on FlexMove Aluminum Conveyors: FS (65 mm), FM (85 mm), FC (105 mm), FL (150 mm), FU (180 mm), and FV (260 mm)

- Max. single product weight: 2.3 kg (5 lbs)

- Max. product accumulation weight: 13.6 kg (30 lbs)

- Max. conveyor speed: 50 m/min (164 ft/min)

- Produces gap of approximately one product length

Operating Requirements:

- Requires photo sensors, pneumatic solenoid valves, wiring and programming

- Rate depends on product size. Contact factory for details

- Dual Vertical Blade Stops

- Horizontal Squeeze Stop with Vertical Blade Stop

- Dimensions

- Manuals & Literature

Dual Vertical Blade Stops

Horizontal Squeeze Stop with Vertical Blade Stop

Dimensions

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Literature | |

| FlexMove Puck Stop Module |