Curved conveyor systems are crucial in many production lines—particularly those dealing with delicate or complex materials that must navigate turns or changes in direction while maintaining accuracy. However, many traditional curved systems come with added complexities: (1) they often require large footprints with extra infeed/outfeed segments, (2) can cause product scuffing during turns, and (3) demand frequent maintenance to keep belts aligned. For industries handling fragile or easily damaged goods, these issues can translate directly into wasted product and added downtime.

Dorner’s new Compact Curve Conveyor (C³) is designed to reduce these complexities and meet the needs of industries looking for a trustworthy compact curved conveyor. Below, we’ll explore the key advantages of curved conveyors, comparing and contrasting them to modular conveyors. We’ll also explore the C³ specifically and compare it with Dorner’s existing modular belt conveyor lineup, including the AquaPruf and 3200 Series modular conveyors.

“The C³ was developed to fill a specific gap in our portfolio – a curved solution that fits into our small, low-profile conveyor line. Unlike our modular chain curves, this belted conveyor eliminates the need for straight sections before and after the curve, substantially reducing the system’s footprint.” – Marco Pardo, Product Manager

Comparing Curved Belt & Modular Conveyors

Dorner’s modular belt conveyors—like the AquaPruf and 3200 Series—are known for their flexibility, especially in wet, washdown, or heavy-duty environments. While these modular platforms excel in high-load or hygienic environments, curved conveyors (like the C³) meet a different set of needs.

Curved Belt Benefits

- Smooth Belt Surface: A fabric belted system is gentle on confectionery, bakery items, or any product that could be marred by an uneven belt surface.

- Low-Profile & Economical: Typically lower in cost and space requirements, offering a simpler, more compact design capable of tight turns without the need for extra infeed/outfeed segments.

- Accurate Product Positioning Through Turns: The C³’s patented curved belt and drive system keeps the product’s leading edge consistent, improving the ease of downstream processes.

- Small Pulleys: Small-diameter pulleys allow for greater accuracy and precision in transferring small, delicate products.

Modular Belt Strengths

- Tough in Demanding Environments: The interlocking plastic modules resist damage and can handle higher loads, making them ideal for applications like heavy product handling or extensive washdowns.

- Complex Layout Possibilities: Modular belts can create multiple curves in a single conveyor path, which is beneficial in space-constrained facilities.

- Wide Range of Belt Types: Cleated, open-grid, and friction inserts are just a few options available to support different product shapes, sizes, and processing requirements.

Key Takeaways:

- Choose Modular for Heavy Loads & Complex Washdown Applications: If you’re moving heavier items or need a belt that can stand up to repeated high-pressure washdowns, Dorner’s modular conveyors (AquaPruf and 3200) might be the best fit.

- Pick the C³ for Delicate Products & Tight Spaces: For small or delicate items that need gentle handling and precise transfers around curves, the C³’s smooth surface and compact design is ideal.

Curve Conveyance Made Simple with Dorner’s C³

Key Takeaways

- Small Pulley, Big Impact. By reducing the pulley size, the C³ can handle product as small as 2 inches, offering seamless transfers without product loss or damage.

- Eliminates Extra Conveyors. Unlike modular curved belts that typically require long straight infeed/outfeed conveyors, the C³’s design minimizes the overall footprint by reducing these additional segments.

- Designed for Delicate Goods. The gentle, curved belt design helps preserve product quality, making it ideal for confectionery, baked goods, and other fragile packaged products.

C³ Highlights

- Compact, Low-Profile Frame. Similar to Dorner’s 2200, 2700, and AquaGard LP lines, the C³ features a low-profile structure that easily fits into tight spaces to transport product between or through production equipment.

- FDA & BISSC Approved. Equipped with stainless steel bed plates and FDA-approved belts and plastic components, the C³ meets BISSC standards—perfect for baked goods, candy, and other packaged food products.

- Quick Belt Change & Minimal Downtime. Easy maintenance is built into the C³ with fast belt-change features (such as the toolless disassembly) and readily available spare parts, ensuring you can maximize uptime in your production line.

Supporting Production Line Integration

Key Takeaways

- Standardized Components & Fast Shipping: Dorner’s modular approach ensures parts are in stock, minimizing downtime and spare parts lead times.

- Consistent Controls & Accessories: The same Dorner design philosophy ensures smooth integration, from guiding accessories to motor mounting options.

- Cross Compatible: The C³ is compatible with Dorner’s other low-profile conveyor lines, including the 2200, 2700, and AquaGard LP series conveyors.

Key Benefits of Dorner’s Compact Curve Conveyor (C³)

Space Optimization

- Compact Design: The low-profile frame of the C³ reduces the conveyor’s overall footprint, making it an ideal solution for tight spaces. This space-efficient design enables the integration of the C³ into existing lines without requiring extensive modifications, maximizing valuable floor space.

- Reduced System Footprint: Unlike traditional modular belt curves that often require long straight infeed and outfeed conveyors, the C³’s seamless design reduces the infeed and outfeed, streamlining the system and further reducing the overall space needed.

Gentle Product Handling

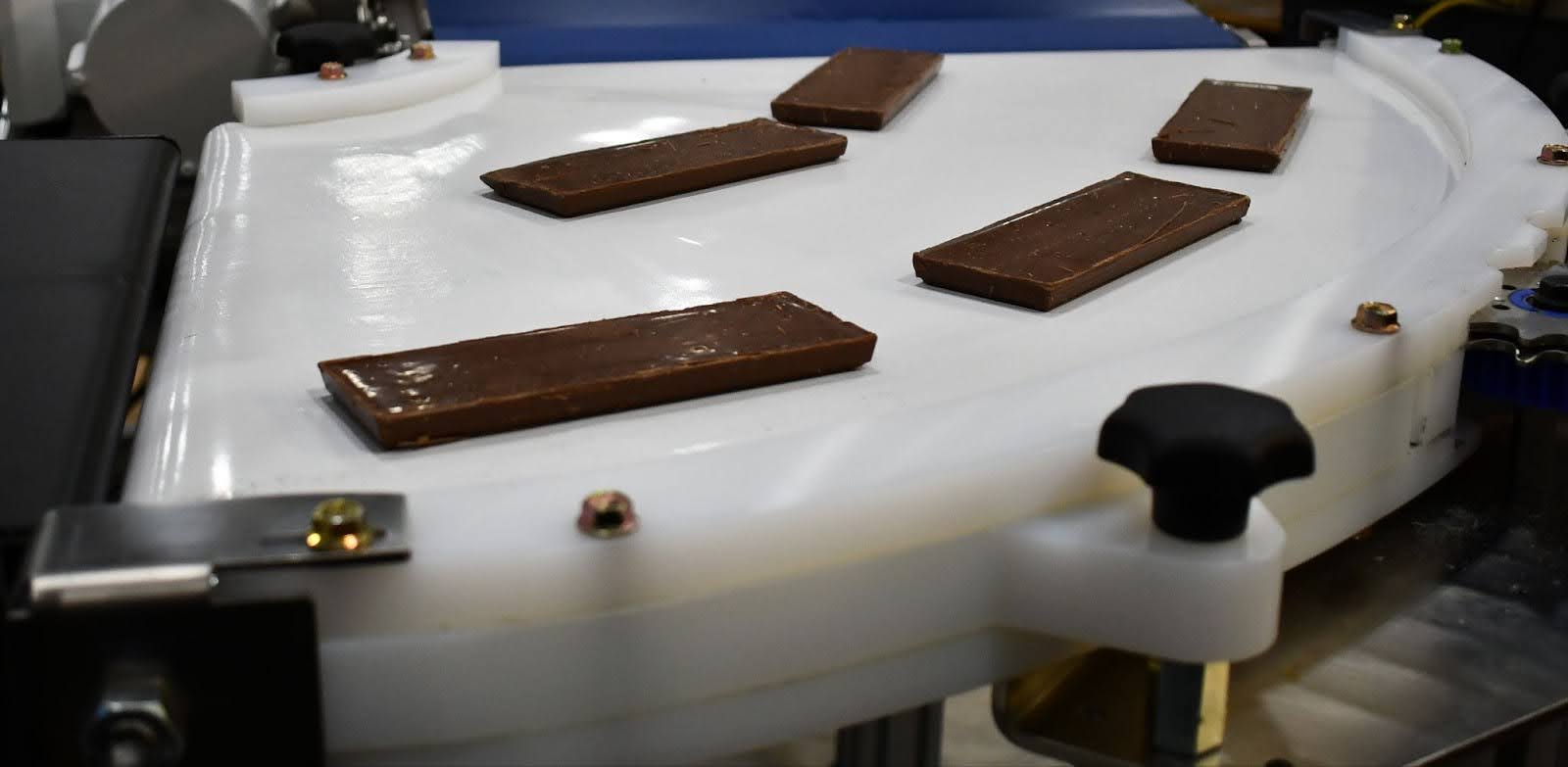

- Smooth Belt Surface: The C³’s fabric-belted system is designed for gentle handling, preventing scuffing, breakage, or deformation of delicate items. This makes it especially suitable for handling confectionery products, bakery items, or any fragile goods that need to maintain their integrity through the curve.

- Precise Product Positioning: The C³’s patented curved belt and drive system ensure that the leading edge of the product and separate lanes remain consistent throughout the curve, preventing misalignment and ensuring the product is correctly positioned for the next step in the processing line.

- Tight Product Transfers: Small pulleys allow the C³ to gently transfer delicate products as small as 2 inches.

FDA & BISSC Compliant

- The C³ is equipped with FDA-approved belts and plastic components and stainless steel bed plates, making it compliant with BISSC (Bakery, Snack, and Confectionery) standards. This ensures that the C³ is food-safe, making it ideal for baked goods, confectionery, and packaged food applications where dry environment wipedowns are required.

Ease of Maintenance

- Quick Belt Change: Designed for minimal downtime, the C³ features a side-driven sprocket system that allows the conveyor to be easily removed and replaced from the system, making maintenance fast and easy. With Dorner’s fast shipping of spare parts, maintenance is far less of a headache, keeping production lines running smoothly with ease.

- Minimal Operational Wear: The low-tension design also reduces wear and tear on the system, ensuring long-lasting reliability and performance.

Seamless Integration with Other Dorner Systems

The C³ is fully compatible with Dorner’s 2200, 2700, and AquaGard LP conveyor lines. This interoperability allows the C³ to be integrated into existing conveyor systems, creating a cohesive and efficient automated line. Whether you’re optimizing an existing line or building a new one, the C³’s flexibility in integration offers significant ease in scaling production.

Applications and Industry Use-Cases

Confectionery & Baked Goods

- Gentle Handling: The C³’s smooth, low-tension belt prevents product scuffing or breakage—ideal for delicate confections like chocolates and pastries.

- Food-Grade Construction: Stainless steel bed plates and FDA-approved plastics align with BISSC requirements, ensuring hygienic transport of baked goods.

Snack Food & Packaged Items

- Accurate Transfers: With small pulleys and precise belt tracking, the C³ accommodates small packages or bags without snagging during turns.

- Reduced Footprint: By eliminating straight infeed/outfeed conveyors, the C³ helps maximize valuable floor space in fast-paced packaging lines.

Pharmaceutical & Nutraceutical

- Smooth Belt Surface: Tablets, blister packs, and other fragile items remain intact as they transition around curves.

- Precision Through Curves: Consistent alignment and laning enables accurate dispensing or labeling downstream, reducing the risk of misfills.

Learn more about the Pharmaceutical industry

Learn more about how we serve the Nutraceutical industry

Health & Beauty Products

- Delicate Product Support: Bottles and lightweight packaging are handled gently, minimizing spillage or label damage.

- Compact Layouts: The C³’s smaller radius and flexible motor placement let you optimize limited production space or integrate into existing lines.

- High Speed: The C³ is capable of high-speed material handling and maintains accurate product positioning even with lightweight materials.

Pet Food & Treats

- Maintain Product Quality: With gentle handling capabilities and tight product transfers, the C³ reduces the risk of damaging product during transportation through the production line.

- Reliable Product Flow: The curved belt design prevents jamming or product loss, key for high-volume operations.

Contract Packaging & Co-Manufacturing

- Versatile Configurations: Whether it’s 45°, 90°, or 180° curves, the C³ adapts to multiple line setups and product types.

- Adaptable Handling Capabilities: With a range of sizes and configurations, the C³ seamlessly handles a wide range of product sizes and materials, from boxes and bottles to pouches and flexible packaging.

Key Takeaways:

- Gentle Product Handling: Ideal for items that must not be scratched, scuffed, or exposed to mechanical stress from belt edges or transfers.

- Sanitary-Friendly Construction: FDA/BISSC-approved construction with simple wipedown and easy accessibility for routine maintenance.

- Flexible Line Layouts: Whether you need a 45°, 90°, or 180° turn, the C³ can optimize workflow in tight spaces or when expanding an existing line.

What Makes the C³ Truly Unique?

Innovative Curved Belt and Drive System

Compact Design Without Sacrificing Performance

Versatility in Belt Options and Customization

Hybrid Integration with Modular Systems

Cost-Effective, Efficient Solution

Ready to Integrate the C³ or Compare Other Dorner Solutions?

FAQs

How do curved conveyors work?

What are the three types of conveyor belts?

The three main types of conveyor belts are flat belt, modular belt, and cleated belt.

Here’s some more information on those different types of conveyor belts:

- Flat Belt: A continuous loop that moves products on a flat surface. Ideal for light-duty applications.

- Modular Belt: Made of interlocking segments, this belt allows for flexibility in handling heavier loads and navigating curves.

- Cleated Belt: Features raised sections that help transport products on inclines or keep items in place.

What is a curve belt?

A curve belt is a specialized conveyor flat belt that allows the conveyor system to move materials along a curved path.

These belts are designed to transition smoothly around corners, reducing the need for additional straight sections and optimizing space. Curve belts are commonly used in food processing, packaging, and material handling to keep the flow of goods uninterrupted.